Project Information

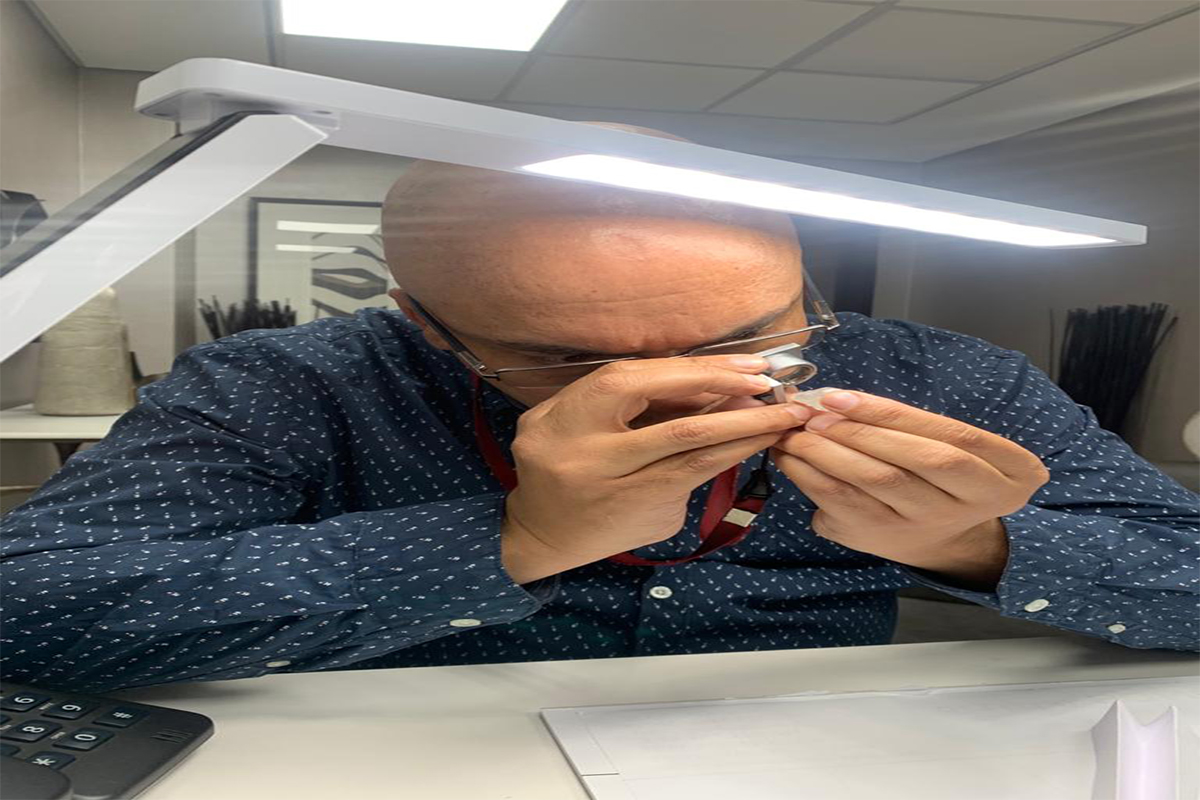

Before cutting the diamond, the cutter will examine the rough diamond and determine the best way to cut it to maximize its value and beauty. This involves analyzing the diamond's shape, size, and inclusions.

- Project : Diamond Cutting And Polishing

- Category : Cut And 4c's

- Clients : Victor Dias

- Date : February 10, 2021

- Status : Completed